Order number | 00516 | Custom processing | No | Article number | 00516 |

Origin | China | Model | HPX | Species | Quick Connector |

Texture | Copper plastic | Scope of application | PU pipe | Temperature resistance | 0-70(℃) |

Pressure resistance | 0-1(MPa) | Installation form | 4,6,8,10,12,16 | Takeover caliber | 01,02,03,04(mm) |

Fluid used: clean compressed air, vacuum

Maximum working pressure: 1.32MPA

Pressure range: 0-90MPA

Environment and fluid temperature: 0-60 degrees Celsius

Use hose: PU hose, nylon tube

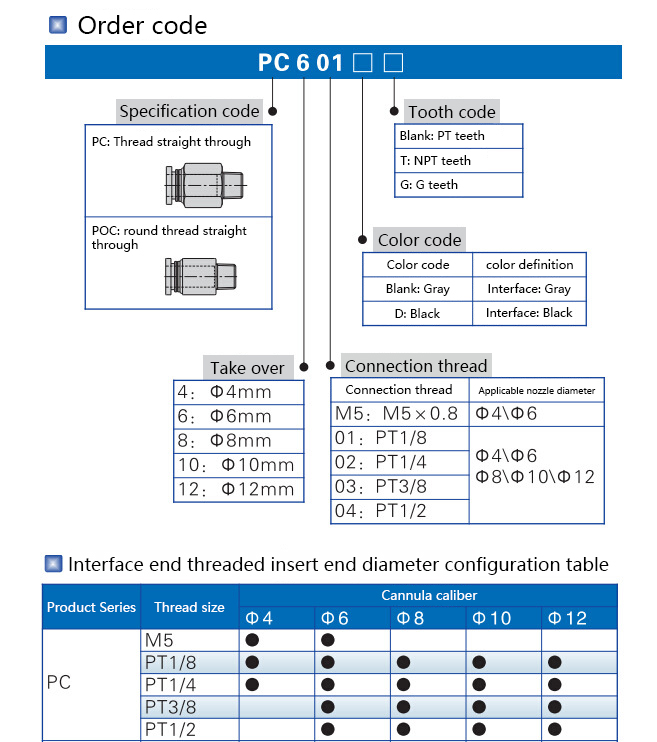

Ordering reference:

LPC 8-02

Serial number Tracheal outer diameter Thread form

LPL 4 01: 1/8

LPB 6 02: 1/4

LPD LPX LPCF 8 03: 3/8

LPM 10 04: 1/2

LPU 12

LPE 14

LPV 16

LPY

LPXL

LPK

LPG

LPEN

LPEND

LPY LPWG

note:

Do not use in fluids other than air and water (usable in machinery and custom production)

If it is used in a place where flowers are produced, it may cause a fire. Therefore, it is prohibited to use it in such a place.

If it is used in hot water above 60 degrees Celsius, the resin may be damaged due to heat and water decomposition, so it is prohibited to use it in this case.

Our products cannot be used in places with static electricity

Do not use fittings that are subject to external loads (bends, twists, pulls) or they may be damaged or leaked

If you use non-our company's air pipe products, leakage or abnormal connection and disassembly may be caused due to the tolerance of the air pipe.

Specifications PU tube Nylon tube

4MMM + -0.1 + -0.08

6MM + -0.12 + -0.1

8MM + -0.12 + -0.1

10MM + -0.15 + -0.12

12MM + -0.15 + -0.12

16MM + -0.15 + -0.16

Please check whether the end face of the trachea is cut at a right angle and whether there is any damage or scratches outside the trachea. When connecting the trachea, please refer to the following. Our products will feel two steps when inserting the trachea into the pipe joint. The segment is the locking part, and the second segment is the seal ring part, which must be inserted into the second segment

The buttons for trachea connection and disassembly are designed to be oval-shaped for easy connection and disassembly. For example, oval-shaped buttons are restricted by the use space. Circular buttons can be specified when ordering. After connecting the pipe joint and the trachea, the trachea must be connected to check whether the trachea can be pulled, and it can be put into use only if it cannot be pulled.

note:

Do not use in fluids other than air and water (usable in machinery and custom production)

If it is used in a place where flowers are produced, it may cause a fire. Therefore, it is prohibited to use it in such a place.

If it is used in hot water above 60 degrees Celsius, the resin may be damaged due to heat and water decomposition, so it is prohibited to use it in this case.

Our products cannot be used in places with static electricity

Do not use fittings that are subject to external loads (bends, twists, pulls) or they may be damaged or leaked

If you use non-our company's air pipe products, leakage or abnormal connection and disassembly may be caused due to the tolerance of the air pipe.

Specifications PU tube Nylon tube

4MMM + -0.1 + -0.08

6MM + -0.12 + -0.1

8MM + -0.12 + -0.1

10MM + -0.15 + -0.12

12MM + -0.15 + -0.12

16MM + -0.15 + -0.16

Please check whether the end face of the trachea is cut at a right angle and whether there is any damage or scratches outside the trachea. When connecting the trachea, please refer to the following. Our products will feel two steps when inserting the trachea into the pipe joint. The segment is the locking part, and the second segment is the seal ring part, which must be inserted into the second segment

The buttons for trachea connection and disassembly are designed to be oval-shaped for easy connection and disassembly. For example, oval-shaped buttons are restricted by the use space. Circular buttons can be specified when ordering. After connecting the pipe joint and the trachea, the trachea must be connected to check whether the trachea can be pulled, and it can be put into use only if it cannot be pulled.

note:

Do not use in fluids other than air and water (usable in machinery and custom production)

If it is used in a place where flowers are produced, it may cause a fire. Therefore, it is prohibited to use it in such a place.

If it is used in hot water above 60 degrees Celsius, the resin may be damaged due to heat and water decomposition, so it is prohibited to use it in this case.

Our products cannot be used in places with static electricity

Do not use fittings that are subject to external loads (bends, twists, pulls) or they may be damaged or leaked

If you use non-our company's air pipe products, leakage or abnormal connection and disassembly may be caused due to the tolerance of the air pipe.

Specifications PU tube Nylon tube

4MMM + -0.1 + -0.08

6MM + -0.12 + -0.1

8MM + -0.12 + -0.1

10MM + -0.15 + -0.12

12MM + -0.15 + -0.12

16MM + -0.15 + -0.16

Please check whether the end face of the trachea is cut at a right angle and whether there is any damage or scratches outside the trachea. When connecting the trachea, please refer to the following. Our products will feel two steps when inserting the trachea into the pipe joint. The segment is the locking part, and the second segment is the seal ring part, which must be inserted into the second segment

The buttons for trachea connection and disassembly are designed to be oval-shaped for easy connection and disassembly. For example, oval-shaped buttons are restricted by the use space. Circular buttons can be specified when ordering. After connecting the pipe joint and the trachea, the trachea must be connected to check whether the trachea can be pulled, and it can be put into use only if it cannot be pulled.

Precautions for using the connector:

1. Make sure that the cut surface of the pipe is vertical, there are no scars on the periphery of the pipe, and the pipe is not oval.

2. When inserting the pipe, be sure to insert it at the bottom of the joint. If the pipe is not inserted, it may cause air leakage.

3. After the pipe is assembled, pull the pipe to make sure that the pipe cannot pull out the joint.

4. Please do not use for other than fluid.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material and easily cause leakage.

7. Don't hit, bend, stretch and prevent damage.

8. Do not use in places where metal powder or sand dust is mixed in. Adhesives will cause poor work or leak.

Precautions during disassembly: Use a suitable tool to remove the pipe joint using the outer hexagonal part of the pipe joint. To remove the sealing material adhered to the opposite side of the fitting. Otherwise, the adhered sealing material may enter the peripheral components and cause failure.